Services & Capabilities

At Valencia Plastics, we manufacture the highest quality Blow Molded and Plastic Injection products for many industries including, Aerospace, Medical, Commercial, Military, and Pharmaceutical.

Start to Finish Manufacturing Services

- High-Quality Plastic Injection and Blow Molding services

- Complete in-house mold shop using CAM software

- Engineering services using CAD software

- We provide guidance and expertise for new Inventors

- Assistance with new product design

- Affordable short production/prototype runs

- Full-scale production runs (open 24/7)

- We offer a wide range of stock bottles

- Wide selection of plastic resin choices to fit your needs

- Product assembly & fulfillment with custom packaging

- Operational Excellence – ISO 9001:2015 compliant

Plastic Injection Molding Capabilities

Materials We Work With

- Acrylonitrile Butadiene Styrene (ABS)

- Acrylic

- Acetal

- Delrin

- Fortron

- High-Density Polyethylene (HDPE)

- High Impact Polystyrene (HIPS)

- Low-Density Polyethylene (LDPE)

- Nylon 6/6

- Polyetheretherketone (PEEK)

- Poly Vinyl Chloride (PVC)

- Polycarbonate

- Polyester

- Polypropylene (PE)

- Polystyrene

- Polyurethane

- Santoprene

- Ultem

- Urethane

- Valox

Product Capabilities

- Large parts up to 7lb. shot size

- Micro parts (weight 1 gram)

- Small parts

- Miniatures

- Multi-component parts (over molding and insert molding)

Mold Process Type

- Single Cavity mold usually aluminum (prototype mold under 15,000 shots).

- Single Cavity Steel mold usually P-20 steel is used (mold life can be from 50K to 1 million shot life).

- Family molds with runner shot off valve for different size parts and colors in the same tool.

- Multi-cavity high production tooling up to 96 cavities with hot runner system.

- Molds that require insert molding and over molding services are also available.

- We process molds that require hydraulic cylinders, unscrewing cores and collapsible cores.

Blow Molding Capabilities

Materials We Work With

- Acrylonitrile Butadiene Styrene (ABS)

- High Density Polyethylene (HDPE)

- Low Density Polyethylene (LDPE)

- Polypropylene (PE)

- Polystyrene

- Polyurethane

- Santoprene

- Kostrate

- K-Resin

Product Capabilities

- Large parts up to 5lb shot size

- Small parts 5 grams

- Multi-component parts (over molding and insert molding)

Mold Process Type

- Single cavity blow mold usually 70/75 aerospace aluminum.

- Multi cavity blow mold with beryllium pinch for longer tool life (mold life is in the millions of parts).

- We run air needle and blow pin blow molds.

- Molds that require inserts or over molded components are used.

Capabilities

Additional Capabilities

- Product assembly

- Custom colors

- Engineering

- Hot stamping

- In-mold labeling injection and blow molding

- Insert molding/over molding

- Mold making in house (Made In America)/with offshore option

- Product development (Inventor Assistance available)

- Screen printing/pad printing

- Secondary operations

- Sonic welding

- Tooling/mold design

- Turnkey solutions

- Warehousing/storage

Lead Times

- Quoted on job by job basis

- Production standard lead times are 2 weeks

- New tooling lead times are 4 to 6 weeks

- Expedited services available

Production Volume

- Custom specialty company

- High volume with storage capacity for on-time delivery

- Low volume

- Small production runs

File Formats

- Auto Cad (DWG)

- Drawing Exchange Format (DXF)

- Graphics Interchange Format (GIF)

- Initial Graphics Exchange Specification (IGES)

- Joint Photographic Experts Group (JPG/JPEG)

- Portable Document Format (PDF)

- Pro-E or Pro/Engineer (DRW/PRT)

- Solid Works (SLDPRT,SLDDRW,SLDDRT)

- Standard for the Exchange of Product Model Data (STEP)

Computer-Aided Design (CAD)

We offer Engineering services using Computer Aided Design (CAD) allowing us to create detailed 3D models of your product. Using the CAD software helps to facilitate part design and allows for more accurate design iterations that are simpler and with a higher precision than previous methods.

In-House Mold Shop

We use only the highest quality steel and aluminum for our molds, and Computer Aided Manufacturing (CAM) software to ensure that your plastic injection or blow molded products are made to your exact specifications.

Stock Bottles

We have a wide variety of stock bottles that can be quickly produced. Get your product to market faster and save money. Call us Today for more information, pricing, and delivery options.

Plastic Injection & Blow Molding

We are full-service plastic injection molding facility, providing the highest quality of plastic injection molded parts ranging from 1 gram up to a 7lb shot. Our state of the art equipment allows us to hold very tight tolerances on plastic parts.

Plastic Resin Choices

We carry a large selection of plastic resins that include ABS, Celcon (Acetal), Polypropylene, HIPS, LPDE. Choosing the right material will ensure optimal performance and manufacturability, as well as save you time and money.

Inventions & Prototyping

If you have an idea or even a scribble on a napkin, Valencia Plastics can help make your concept into reality. Utilizing the latest technology in mold making and plastic injection manufacturing, our team can quickly deliver high-quality prototypes at an affordable price.

Speed-To-Market

If speed-to-market is important to you, and you need a partner with rapid prototyping capabilities then look no further. Our designers and engineers will work closely with you on getting your product to market quickly and on budget.

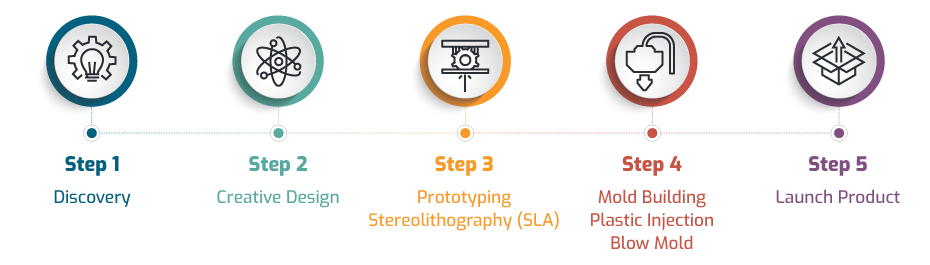

Bringing your ideas off the notepad and into production is our specialty. Our Concept to Shelf process offers you flexibility and greater control over the manufacturing process.

Step 1: Discovery

At some point in our life, we have all identified a need in the market and came up with a great idea that would satisfy that need. That’s the easy part. The hard part is turning that great idea into a successful product that people are willing to pay for. The difference between success and failure depends on how well you understand the market and how thorough your research is.

The most important step would be to conduct a search to determine if your idea has already been patented or publicly disclosed. You can make a very brief preliminary search online, but the best way is to hire an experienced patent attorney. If your attorney did not find any evidence of public disclosure then you are on the right track for making your idea a reality.

Step 2: Creative Design

Once the discovery process is complete, its time to move on to the fun part. The product design phase. Our engineers with decades of market experience will assist you in taking the right path in bringing your product to life. Using the latest CAD software they will provide 3D renderings: photo-like drawings that can be rotated and interacted with to help you get a sense of what your product will look like once the project is complete. This process takes about 3 to 5 business days.

With final design in hand its time to build a prototype or move directly into the mold phase.

Step 3: Prototyping | Stereolithography (SLA)

Seeing is believing and nothing beats being able to touch and hold your new product design. While not a required step, Stereolithography (SLA) provides accurate models and patterns in record time so that you can touch and feel your product and be able to make modifications before creating a mold. SLA is among the most accurate and precise rapid prototyping technologies available. SLA models and patterns can be produced in a matter of days from any popular CAD system. Starting with CAD geometry, IGES or STL data, SLA models are ideal for use as concept models, form and fit studies because of their accuracy and ability to reproduce fine details. This process takes about 2 to 3 days.

Step 4: Mold Building | Plastic Injection | Blow Mold

With the approved design in hand, we are ready to make the mold to bring your project to production. We work diligently and under tight deadlines to meet your specific needs and supply the best plastic injection and blow molds in the industry. Our tooling is built to meet your exact specifications and requirements to ensure your product is a success. This step takes anywhere from 2 to 5 weeks depending on how complex the mold is.

Step 5: Launch Your Product

The final step is launching your approved and tested product design into the market and on store shelves. Our project managers will work closely with you on managing the production schedule and ensure that your product is made to the highest quality standards. We guarantee that the final product will meet or exceed your expectations. Production usually starts about one week after your first article sample is approved and we’ll continue production until your order is completely fulfilled.

Industries We Serve:

Nutritional

Nutraceutical

Food

Pet Foods

Aerospace

Agricultural

Architectural

Construction

Consumer goods

Dental

Electrical

Health supplements

Marine

Automotive

Medical

Military

Oil Field Industry

Optical

Packaging

Pharmaceutical

Transportation

Featured Clients